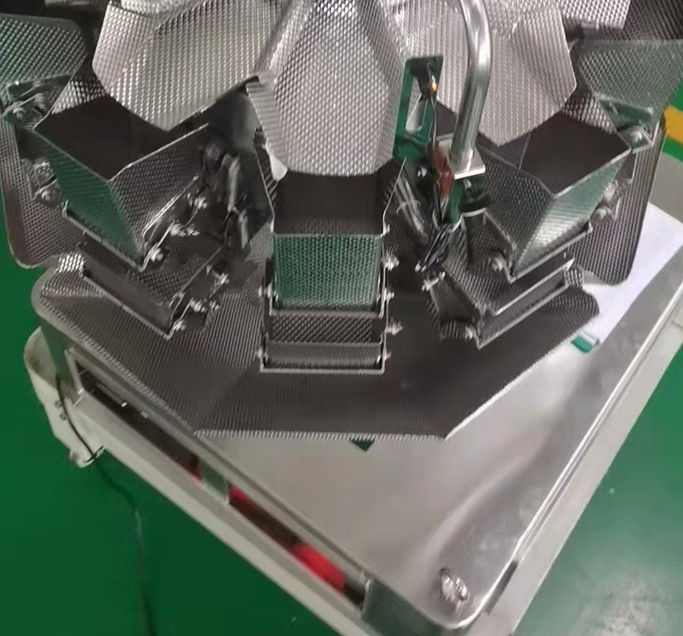

14 Heads Multihead Weigher Coated 2.5 L Stainless Steel 304 Dimple Plate

14 Heads 2.5 L Coated Multihead Weigher Application:

It is widely used for weighing Dried Fruits, candy, chocolates, potato chips, plantain chips, seeds, nuts, jelly, Animal feed, petfood, Potato Chips, beans sticky products, frozen products etc.

14 Heads 2.5 L Coated Multihead Weigher Specification:

| Model |

TY-14H2.5L |

| Max. Weighing (one hopper) |

2.5L |

| Weighing Accuracy |

x (0.5) |

| Min. Scale Interval |

0.1g |

| Hopper Q’ty |

14 heads |

| Hopper Volume |

2.5L |

| Packing Speed |

120 bpm (empty bags) |

| Power Supply |

AC220V ±10% 50HZ/60HZ, 2.5KW |

| Machine Dimension( L*W*H) |

1140*1140*1853mm |

| Packing Weight |

500KGS |

14 Heads 2.5 L Coated Multihead Weigher Features:

All stainless steel/aluminum made.

Auto-pause when there is a material shortage.

High precision and durable load cell.

Help menu to understand each function and parameters.

Multi language touch screen interface.

14 Heads 2.5 L Coated Multihead Weigher Configuration/Advantages:

HBM ultra precision Load cells.

All machinery units are Inter-changeable, easy maintenance and reparation.

Resistant for Water spraying and humidity.

Special climatization design for frozen environment optional

Auto vibration magnitude adjusting to adapt different products or weights.

Sequential hopper discharging to avoid congestions or blockage.

Overweight signal and Auto-rejection system.

Dysfunctional weighing head can be suspended to continue production.

Leak proof hoper, Corrugated hopper, SUS 316, coated optional

Counting Application

How multihead weighing works:

A 'typical target' weight per pack might be 100 grams of a product. The product is fed to the top of the multihead weigher where it is dispersed to the pool hoppers. Each pool hopper drops the product into a weigh hopper beneath it as soon as the weigh hopper becomes empty.

The weigher's computer determines the weight of product in each individual weigh hopper and identifies which combination contains the weight closest to the target weight of 100g. The multihead weigher opens all the hoppers of this combination and the product falls, via a discharge chute, into a bagmaker or, alternatively, into a distribution system which places the product, for example, into trays.

Dispersion is normally by gravity, vibration or centrifugal force, while feeding can be driven by vibration, gravity, belts, or screw systems.

An extra layer of hoppers ('booster hoppers') can be added to store product which has been weighed in the weigh hoppers but not used in a weighment, thus increasing the number of suitable combinations available to the computer and so increasing speed and accuracy.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!